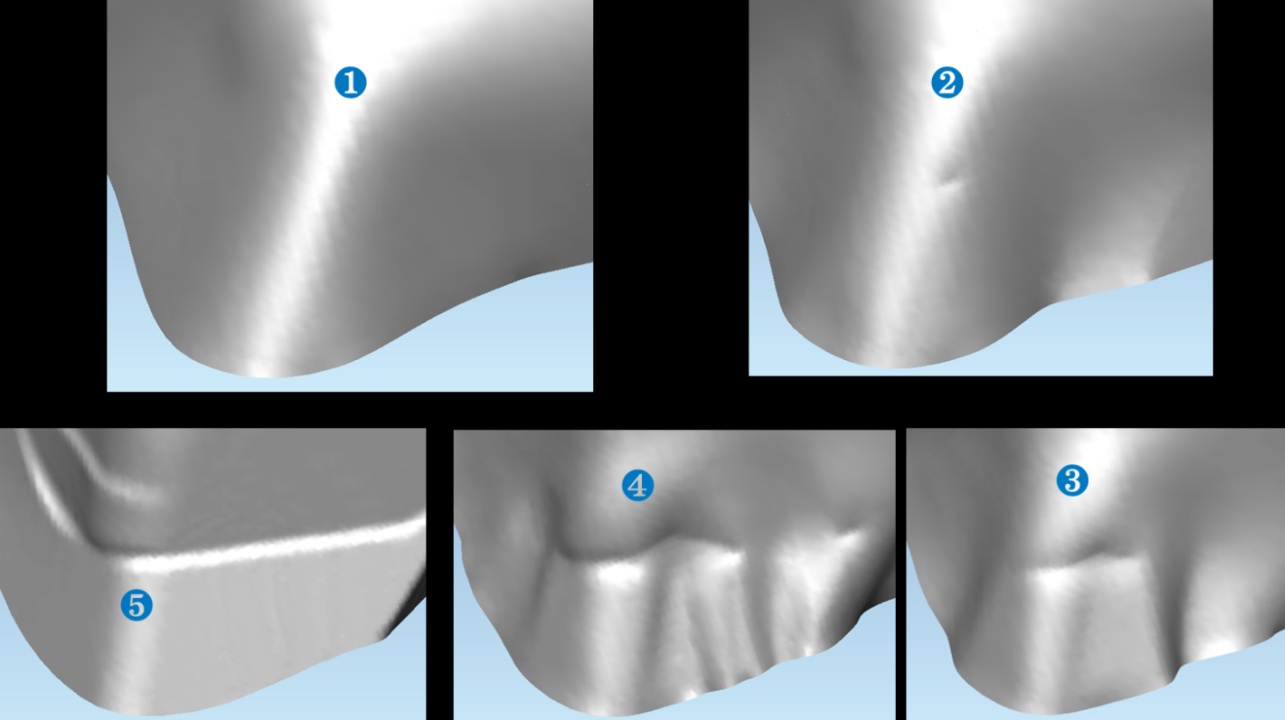

Wrinkles

Especially in a hot forming process, wrinkles can come and go. If they are not flattened out at the end they could even destroy a die. PAM-STAMP simulates wrinkles with no compromises as they would occur in reality, including folding. Only an explicit simulation scheme can do that thanks to the many small time steps and the ability to manage significant geometrical non-linearity’s without slowing down or even stopping the simulation.

PAM-STAMP Features

- Topology check, cleanup and repair

- Material cost estimation

- Die face design next generation based on B-Spline geometry

- Fast link with simulation

- Accurate numerical methods

- Geometrical drawbeads

- Springback - Kinematic Hardening Model

- Ironing

- Triple speed mode for breathtaking short simulation times

- Precise prediction of wrinkles including folding – no numerical flattening

- Blank & Trim Line Optimization

- Springback of High Strength Steel

- (Multi-operation) compensation

- Virtual prototyping of the full stamping chain

- Cosmetic defects

- Customization

- High quality results without tradeoffs in cost and time

- Hot Forming , End-to-End Virtual Prototyping

- Chaining with manufacturing engineering and assembly prototyping

- Virtual Reality