Ironing

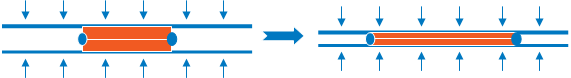

Ironing is used to control springback, in particular with high strength steel, and is a natural phenomenon in processes like coining.

Precision forming of processes where ironing or coining occurs requires the use of a particular Finite Element (FE) formulation, which takes into account through thickness stress.

The normal shell formulation is not sufficient to describe this phenomena, as the stress and strains in the normal element are not described well enough. Therefore, PAM-STAMP features a particular element to simulate ironing: TTS - Through Thickness Stress element.

This element takes into account thinning, normal stress and 3D plasticity induced by bilateral contacts. It is activated automatically when ironing phenomena appears. It is compatible with the Yoshida kinematic hardening model which means that it can be used for advanced springback simulations. Grey: real test with/without ironing Red: PAM-STAMP results without ironing Blue: PAM-STAMP results with ironing

PAM-STAMP Features

- Topology check, cleanup and repair

- Material cost estimation

- Die face design next generation based on B-Spline geometry

- Fast link with simulation

- Accurate numerical methods

- Geometrical drawbeads

- Springback - Kinematic Hardening Model

- Ironing

- Triple speed mode for breathtaking short simulation times

- Precise prediction of wrinkles including folding – no numerical flattening

- Blank & Trim Line Optimization

- Springback of High Strength Steel

- (Multi-operation) compensation

- Virtual prototyping of the full stamping chain

- Cosmetic defects

- Customization

- High quality results without tradeoffs in cost and time

- Hot Forming , End-to-End Virtual Prototyping

- Chaining with manufacturing engineering and assembly prototyping

- Virtual Reality