Predict & Correct Manufacturing Defects with Plastic Injection Molding Simulation

As part of its continuous development in the world of plastics manufacturing, ESI has teamed up with TORAY Engineering to become the 2017 exclusive distributor of 3D TIMON software in Europe and the Americas.

3D TIMON is used by the industry to address manufacturing challenges for a wide range of processes such as:

- Plastic Injection Molding (fiber reinforced or not)

- Sheet Molding Compound (SMC)

- Bulk Molding Compound (BMC)

- Thermo-compression of thermoplastic materials

3D TIMON simulation allows the user to predict and correct manufacturing defects such as:

- Shortage of resin

- Burring

- Burning

- Weld line

- Flow marks

- Warpage

- Fiber orientation and volume content

The manufacturing simulation results can be transferred easily to static or dynamic structural analysis via a direct export from 3D TIMON or through the DIGIMAT application.

Specific features of 3D TIMON software include:

- Short computation time thanks to a “Light3D” patented technology

- Robustness with the capability to handle low quality geometrical data

- Extensive material database including more than 2,500 plastic references

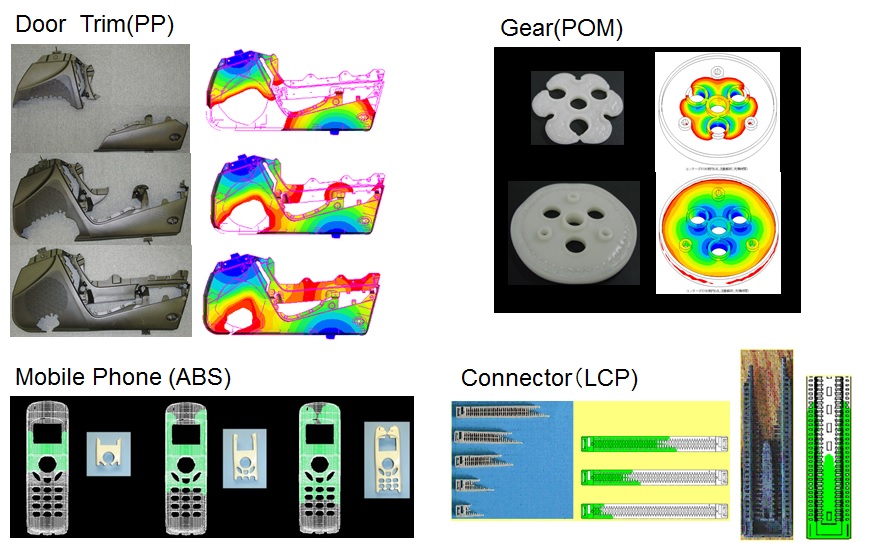

3D TIMON Plastic injection examples, from small electronic components to large automotive parts