From Design/Concept to Try-out

For any given metal forming process, it is possible today to conceive everything in a virtual engineering equivalent from detailing customer requests to virtually inspecting the final product, as well as setting-up the production facilities. This includes material cost estimation, die design and feasibility, part design validation and tooling design and forming processes.

Below you will find a selection of the milestones and elements of a virtual stamping engineering process which will work with stamping simulation software and solutions from ESI - from sheet metal stamp simulation to style, design, part and die production – and beyond.

PAM-STAMP Features

- Topology check, cleanup and repair

- Material cost estimation

- Die face design next generation based on B-Spline geometry

- Fast link with simulation

- Accurate numerical methods

- Geometrical drawbeads

- Springback - Kinematic Hardening Model

- Ironing

- Triple speed mode for breathtaking short simulation times

- Precise prediction of wrinkles including folding – no numerical flattening

- Blank & Trim Line Optimization

- Springback of High Strength Steel

- (Multi-operation) compensation

- Virtual prototyping of the full stamping chain

- Cosmetic defects

- Customization

- High quality results without tradeoffs in cost and time

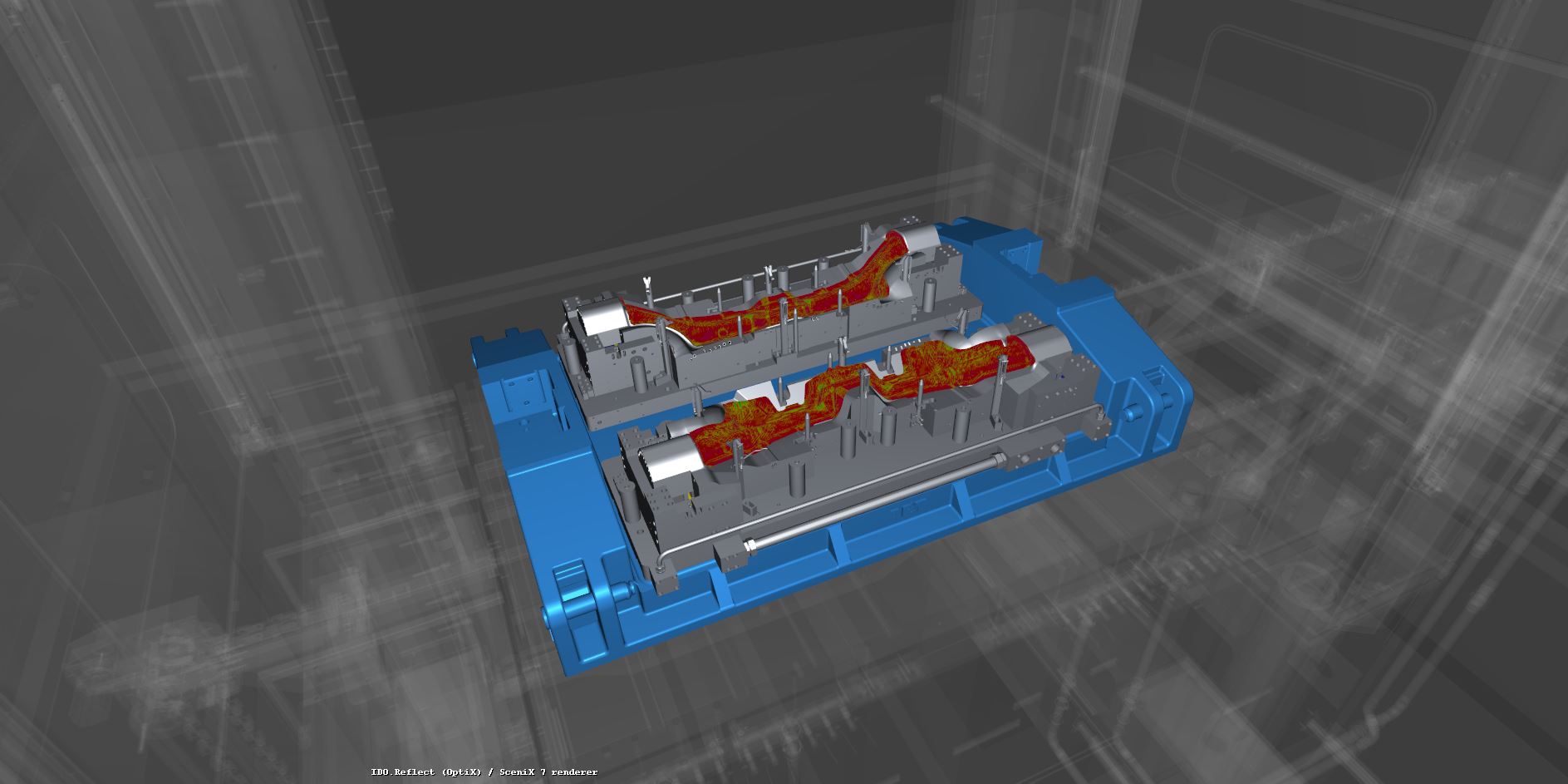

- Hot Forming , End-to-End Virtual Prototyping

- Chaining with manufacturing engineering and assembly prototyping

- Virtual Reality