Draping and Thermoforming Simulation

PAM-FORM, a composite forming simulation module within PAM-COMPOSITES, is used to simulate the preforming process of dry textiles or the thermoforming process of fiber reinforced composite materials made of thermoset or thermoplastic resins (organo-sheets).

PAM-FORM allows you to model a wide range of processes including:

- stamping using two rigid molds

- rubber pad forming

- composites thermoforming

- diaphragm forming pre-pregs forming simulation

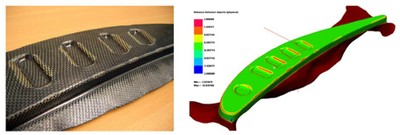

Preforming simulation of an automotive B-Pillar

This module can be used to predict phenomena such as:

- fiber orientation

- thickness distribution

- optimum initial flat pattern

- strains

- stresses

- bridging

- wrinkling

Additionally, these results are available at the laminate level as well as the ply level, allowing you to predict a case of internal wrinkles, for example.

PAM-FORM includes material models for UD (UniDirectional), NCF (Non Crimp Fabric), woven fabric, dry textile, thermoset prepreg and organo-sheet.

With PAM-FORM, manufacturing defects are eliminated and product quality is improved upfront in the product development process, before any tools are cut, thanks to optimization of the following areas:

- tool velocity

- temperature and pressure cycle

- clamping conditions and force

- laminate sequence, ply orientations

- tooling design

Simulation can also be used later in the process to correct manufacturing issues after they are identified.

ESI group has a webinar covering PAM-FORM.