Customization

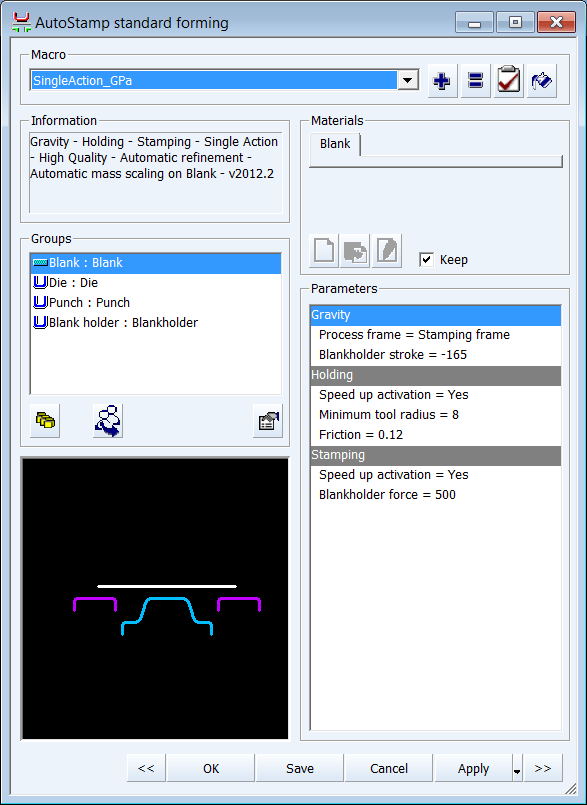

It is possible to customize PAM-STAMP with dedicated toolbars and process macros. This allows you to simplify and automate any stamping process.

Process macros allow the customization of any die operation or completion of the process in a way that users must fill only actual process data to complete the setup of a process simulation. Consequently, no knowledge of the methods of Finite Elements or numerical methods is needed to set up and run a process simulation.

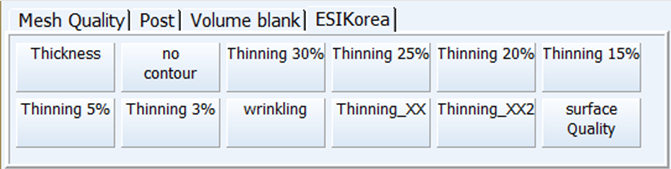

Customizable key board shortcuts allow 1-click data check or post-processing.

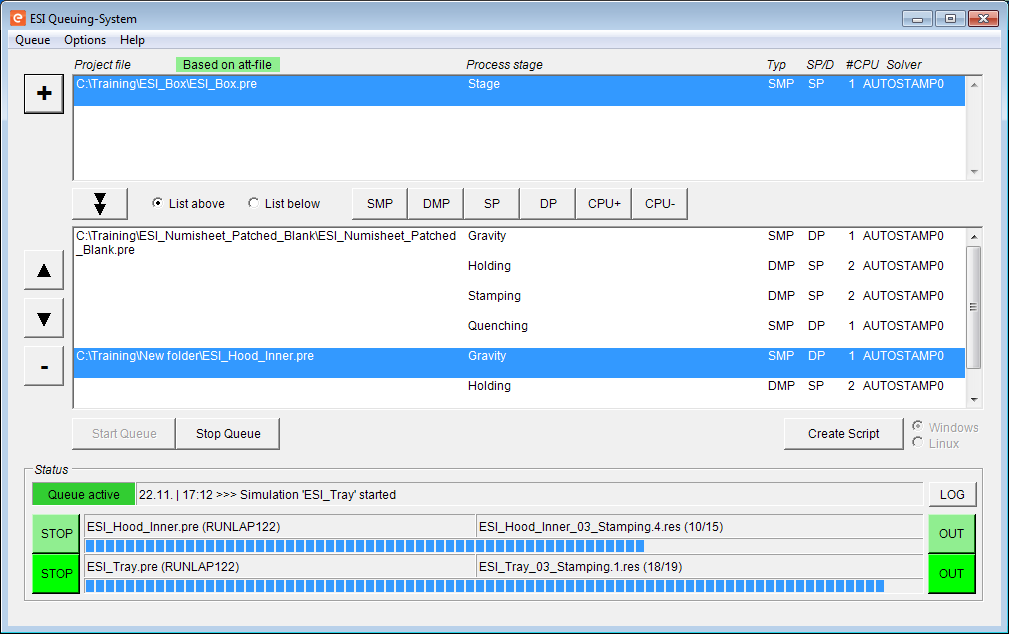

You can also add external programs to the drive, for example, to the solver or to schedule jobs.

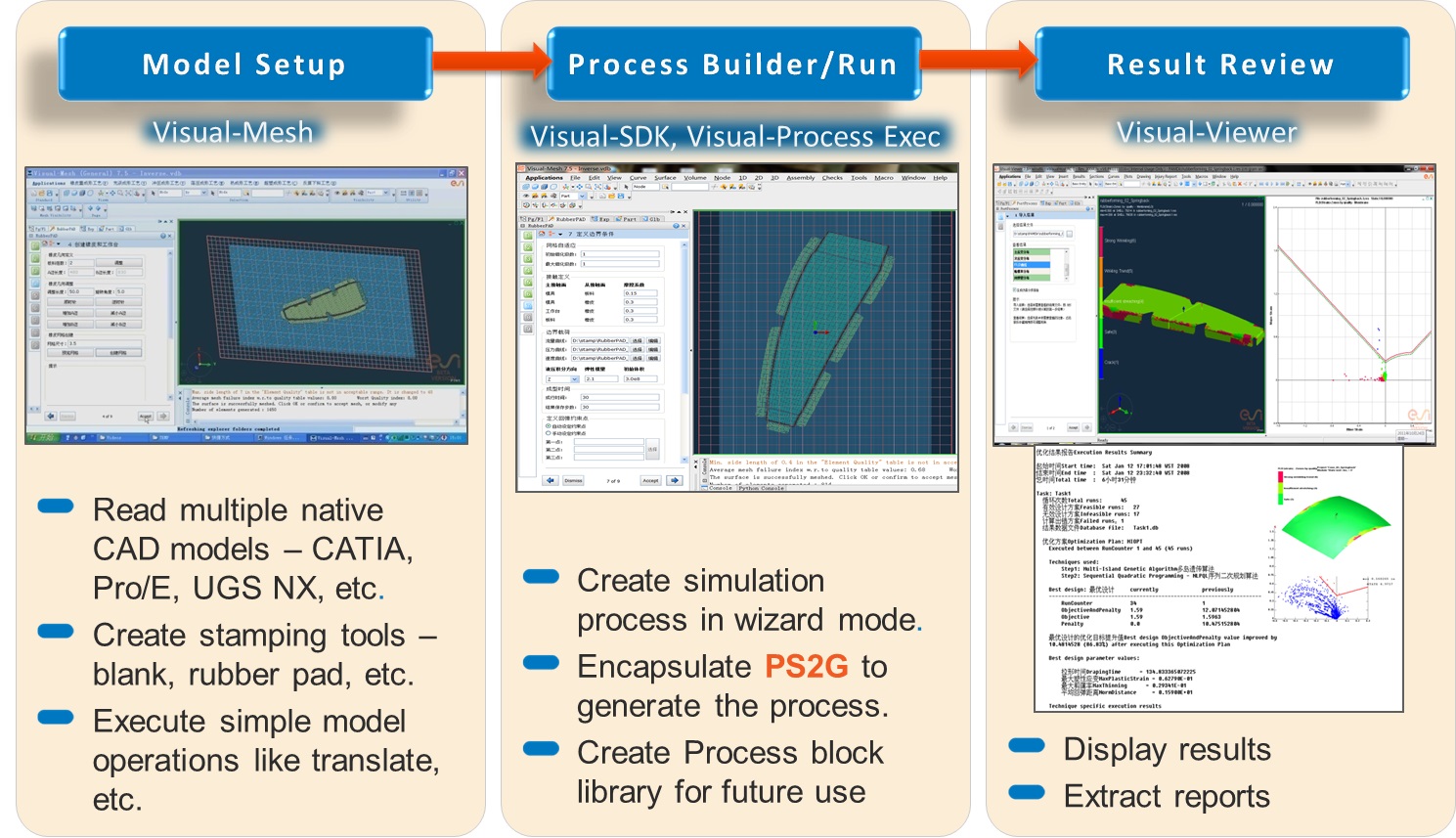

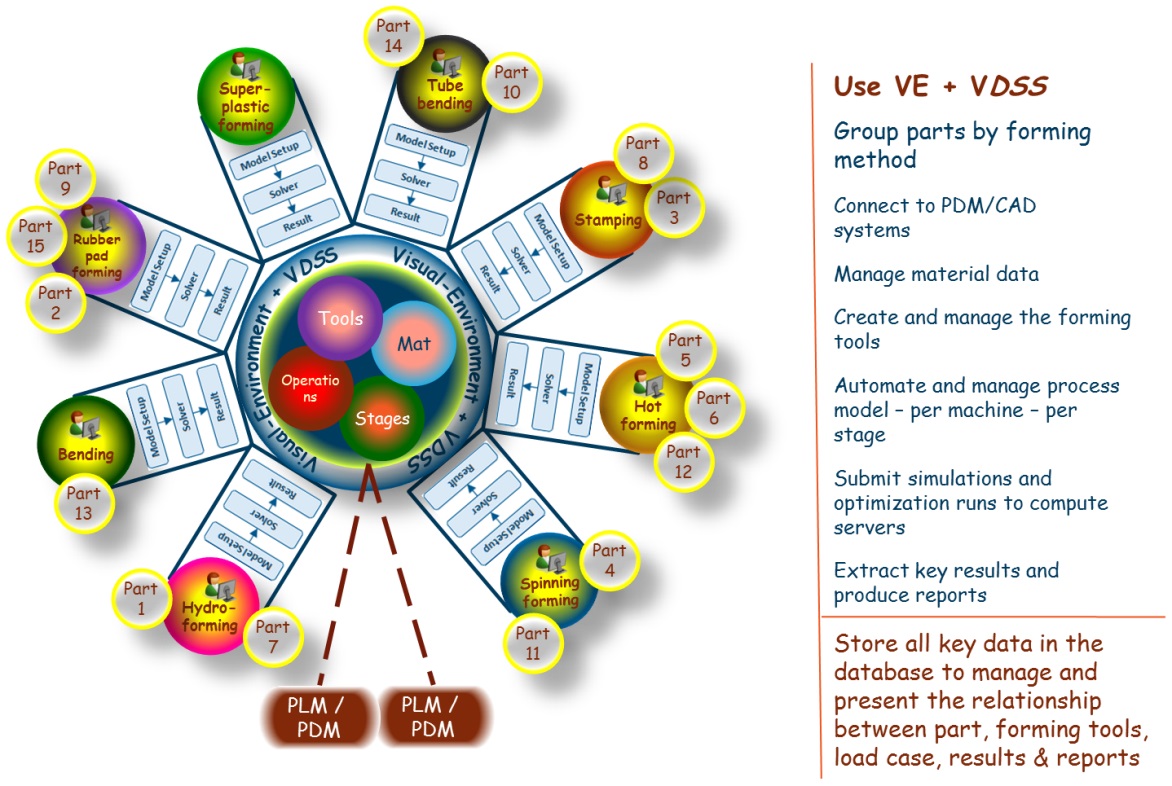

It is even possible to move PAM-STAMP into the background of completely customized processes in Visual Environment.

PAM-STAMP Features

- Topology check, cleanup and repair

- Material cost estimation

- Die face design next generation based on B-Spline geometry

- Fast link with simulation

- Accurate numerical methods

- Geometrical drawbeads

- Springback - Kinematic Hardening Model

- Ironing

- Triple speed mode for breathtaking short simulation times

- Precise prediction of wrinkles including folding – no numerical flattening

- Blank & Trim Line Optimization

- Springback of High Strength Steel

- (Multi-operation) compensation

- Virtual prototyping of the full stamping chain

- Cosmetic defects

- Customization

- High quality results without tradeoffs in cost and time

- Hot Forming , End-to-End Virtual Prototyping

- Chaining with manufacturing engineering and assembly prototyping

- Virtual Reality