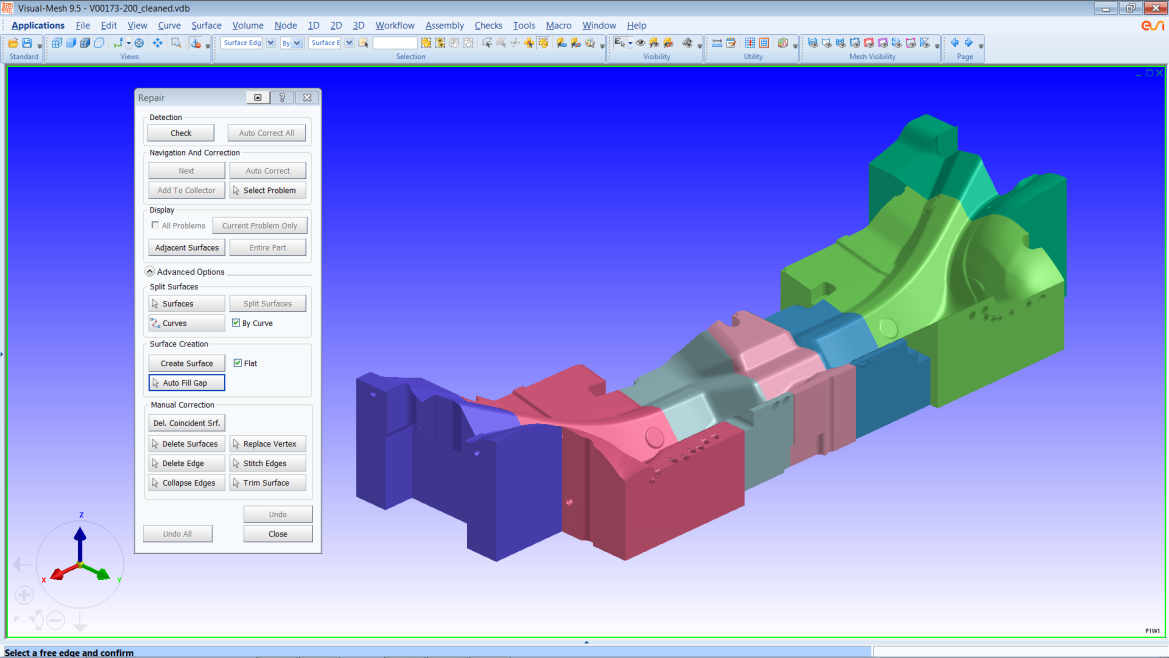

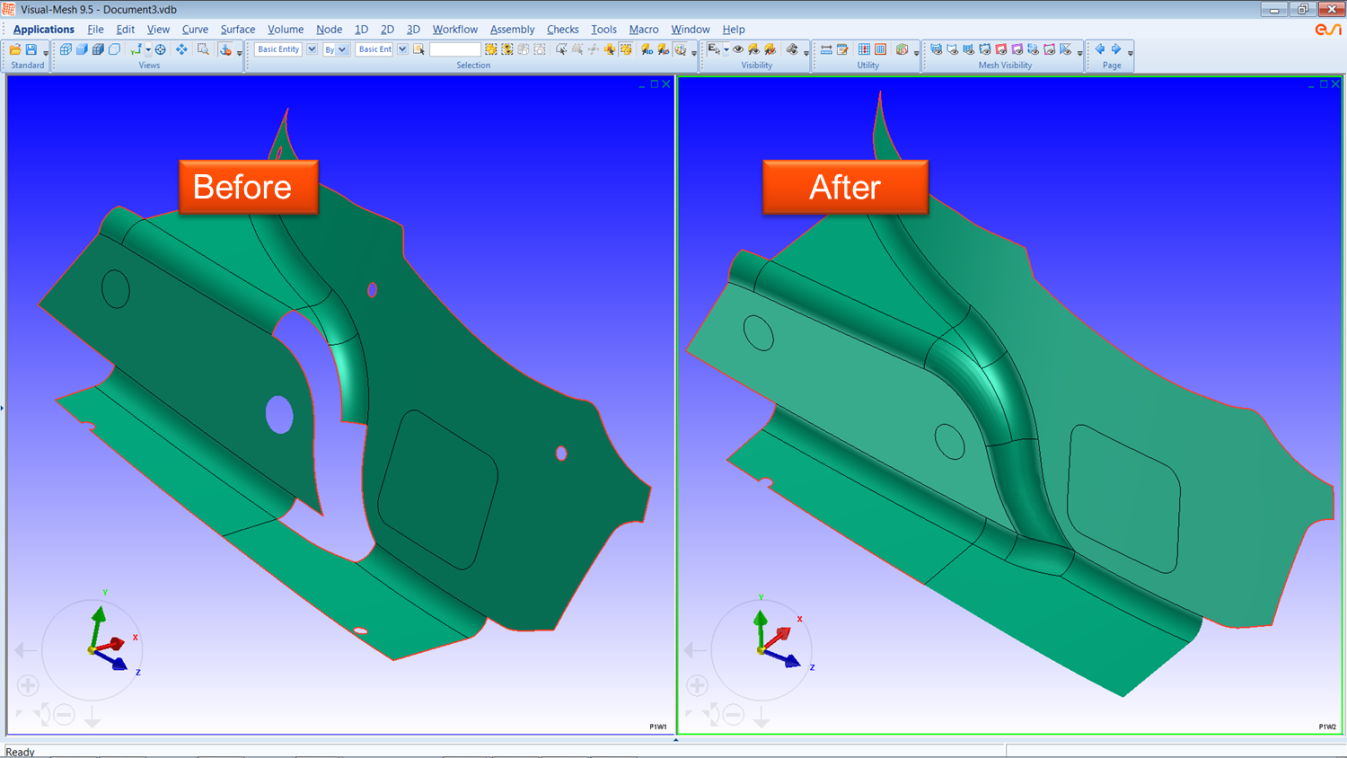

Topology Check, Clean up and Repair

An accurate description of the contact surfaces as the basis for an accurate mesh is the key to accurate results. This is essential from the beginning especially if one is forced to work with foreign die faces and exchange data between different systems. Topology problems in the geometry might occur. It might be necessary to fill holes and repair cracks or to improve geometry in a way that the meshing of the tool surface yields the best possible simulation results.

Of course one can always choose the automatic path but, in the case of a low quality topology, this might lead to a lower result quality and consequently in unidentified cracks or wrinkles. In order to be able to work with the best possible topology, VISUAL MESH allows checking, clean up and repair of any topology quickly before the simulation work starts. It is also possible to modify geometry, and to repair any kind of already generated meshes, no matter in which system they were done. Any topology or mesh is, therefore, in a status to provide best possible simulation results, using accurate contact.

PAM-STAMP Features

- Topology check, cleanup and repair

- Material cost estimation

- Die face design next generation based on B-Spline geometry

- Fast link with simulation

- Accurate numerical methods

- Geometrical drawbeads

- Springback - Kinematic Hardening Model

- Ironing

- Triple speed mode for breathtaking short simulation times

- Precise prediction of wrinkles including folding – no numerical flattening

- Blank & Trim Line Optimization

- Springback of High Strength Steel

- (Multi-operation) compensation

- Virtual prototyping of the full stamping chain

- Cosmetic defects

- Customization

- High quality results without tradeoffs in cost and time

- Hot Forming , End-to-End Virtual Prototyping

- Chaining with manufacturing engineering and assembly prototyping

- Virtual Reality