Triple Speed Mode for Explicit Simulations

A new solver option in PAM-STAMP allows analysis speed up in the same manner as conventional numerical tuning, but without a loss in quality. Specifically, a 3-4X analysis speed up in the drawing phase, with no associated loss of quality, allows these high quality feasibility studies to be completed within the same time constraints as conventional feasibility studies.

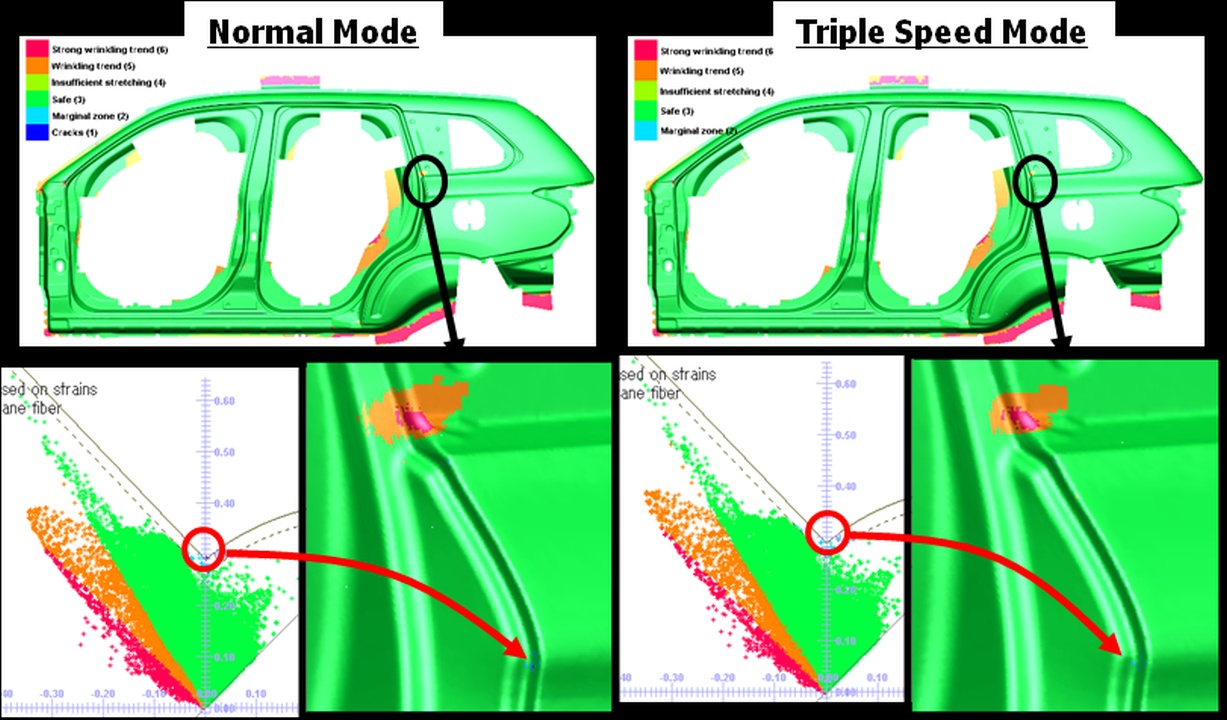

In combination with multi-core processors, very short simulation times can be achieved. With the new solver option and a four core CPU, a total speed up of 12-15 X is possible compared to a one core simulation without the new solver option. Simulation times are now short enough for formability stage precision to be used in the early feasibility phase – all with precision forming quality provided by PAM-STAMP. Consequently, it is no longer necessary to tune explicitly simulations by numerical means such as mass scaling, numerical settings and mesh coarsening, to achieve feasibility run time and consequently pay with a loss of quality. Moderate baseline settings can be used in the feasibility stage. Because the new solver development is not at the expense of quality, it is also applicable in the validation/formability phase. Consequently, it is possible to achieve with standard baseline settings for conservative engineering, the same simulation time as with tuned baseline settings, or even less. With the new solver, it is also no longer necessary to use coarser meshes or any other kind of model simplifications to achieve less simulation time. This allows for high-quality results with a reasonable simulation time at the earliest stage possible. The figure below shows an efficiency of the triple speed mode. The model used for the verification was provided from Mitsubishi Motors. Without loss of quality, calculations with triple speed mode are faster by a factor of 3.7 compared to the normal mode.

PAM-STAMP Features

- Topology check, cleanup and repair

- Material cost estimation

- Die face design next generation based on B-Spline geometry

- Fast link with simulation

- Accurate numerical methods

- Geometrical drawbeads

- Springback - Kinematic Hardening Model

- Ironing

- Triple speed mode for breathtaking short simulation times

- Precise prediction of wrinkles including folding – no numerical flattening

- Blank & Trim Line Optimization

- Springback of High Strength Steel

- (Multi-operation) compensation

- Virtual prototyping of the full stamping chain

- Cosmetic defects

- Customization

- High quality results without tradeoffs in cost and time

- Hot Forming , End-to-End Virtual Prototyping

- Chaining with manufacturing engineering and assembly prototyping

- Virtual Reality