Cosmetic Defect Prediction with PAM-STAMP

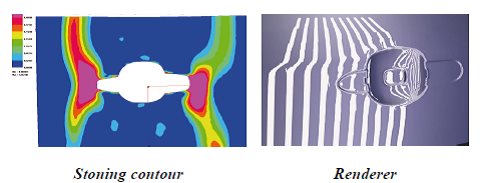

The apparition of cosmetic defects is deeply linked to springback phenomenon. The detection of such small defects is thus only possible with a very precise simulation of springback, which has been proved to be possible with PAM-STAMP. It features new dedicated defect contours based on stoning or sensor for detection of the defects and their quantification. With such contour the user can easily localize the defects as it is done in the workshop and measure their depth and area.

AETHRA Automotive Systems anticipates critical aspect issues on large automotive body components with PAM-STAMP

Download the full Customer Success Story:

AETHRA Automotive Systems, with the help of ESI South America in Brazil, significantly improved the results in prediction and resolution of surface defects in external panels using PAM-STAMP . Today, to satisfy customer needs, we can test different strategies in the process development because we have confidence that we will see the same behavior in try-out.

A. Micheletti Viana, Mechanical Engineering - Formability

Wellington Caetano Soares, Mechanical Engineering - Formability

Arlem Picinin Campos, Simulation Manager

PAM-STAMP Features

- Topology check, cleanup and repair

- Material cost estimation

- Die face design next generation based on B-Spline geometry

- Fast link with simulation

- Accurate numerical methods

- Geometrical drawbeads

- Springback - Kinematic Hardening Model

- Ironing

- Triple speed mode for breathtaking short simulation times

- Precise prediction of wrinkles including folding – no numerical flattening

- Blank & Trim Line Optimization

- Springback of High Strength Steel

- (Multi-operation) compensation

- Virtual prototyping of the full stamping chain

- Cosmetic defects

- Customization

- High quality results without tradeoffs in cost and time

- Hot Forming , End-to-End Virtual Prototyping

- Chaining with manufacturing engineering and assembly prototyping

- Virtual Reality