SRubber-pad Forming with PAM-STAMP

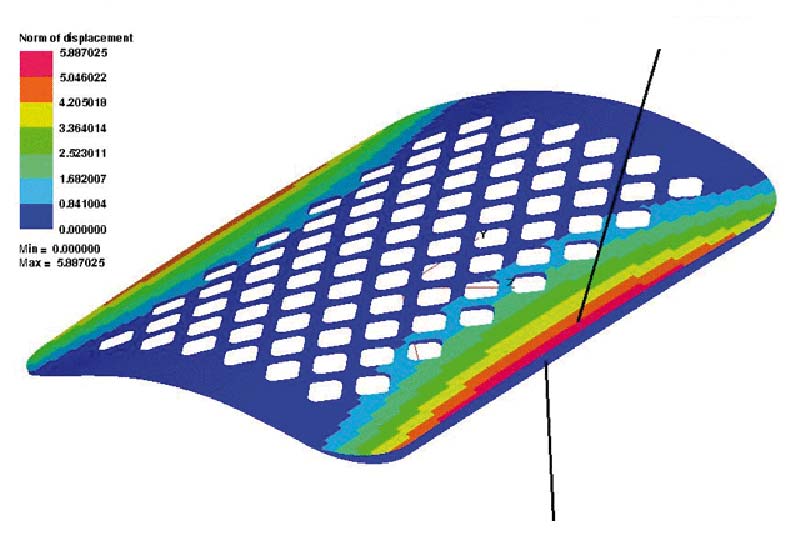

For small volume manufacturing, mainly in aerospace, rubber-pad forming offers an interesting manufacturing technique allowing very complex shapes. Also, for exclusive automotive outer parts, a superior surface quality can be achieved as there is no punch in contact with the part. With PAM-STAMP, the rubber-pad forming process can be defined virtually to find the best process parameters for pressure build-up etc. Also springback can be calculated and the compensation thereof.

Harbin Aircraft Industry successfully implements rubber pad forming simulation using PAM-STAMP

Download the full Customer Success story

“ With PAM-STAMP, we can successfully control the quality of our products. What’s more, both the cost and the time can be decreased by thirty or even fifty percent. It’s become an essential tool for our job.”

Mr. Liu Junji, Vice-CTO of Harbin Aircraft, Industry Group Co. Ltd.