Roll- and Table Top Hemming

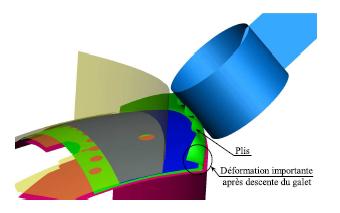

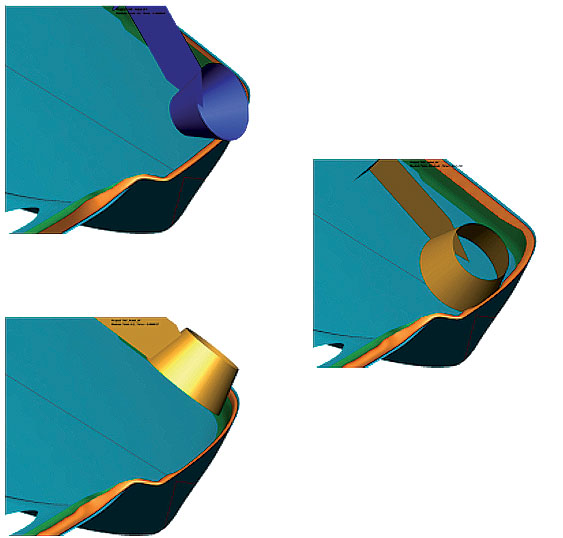

The continuing trend of increasing the number of variants in a car while lowering the number of cars produced requires cost effective manufacturing methods and body in white concepts like roll hemming. This procedure is very flexible and requires only moderate investments. It is the target of this simulation to avoid fixtures, programming and tests during the prototype phase and pilot series.

Besides an optimal and error-free hemming process, the focus of the simulation is on the resulting shape deviation of the assembly caused by the spring back of the components and the hemming. The "roll in" of the final outer edge can also be evaluated.

A user-friendly interface inside PAM-STAMP defines the physical process similarly to the programming of a hemming roll guided by a robotic arm. This allows one to systematically optimize existing experience and stratégies to control possible resulting shape deviations. The position of the part's trim lines that are essential for hemming can be optimized for the proceeding operation sequence of the respective single parts. PSA PEUGEOT CITROËN uses PAM-STAMP for Successful Roll Hemming Simulation on Vehicle Assembly Lines

Read the full Customer Success.

"The most significant state-of-the-art physical parameters identified by PSA’s hemming specialists were integrated into PAM-STAMP. Validated through real-life industrial cases, this new tool has quickly become essential to guarantee successful product definition and process reliability."

Patrice Auger, R&D Manager for Assembly Processes, PSA-Peugeot-Citroën