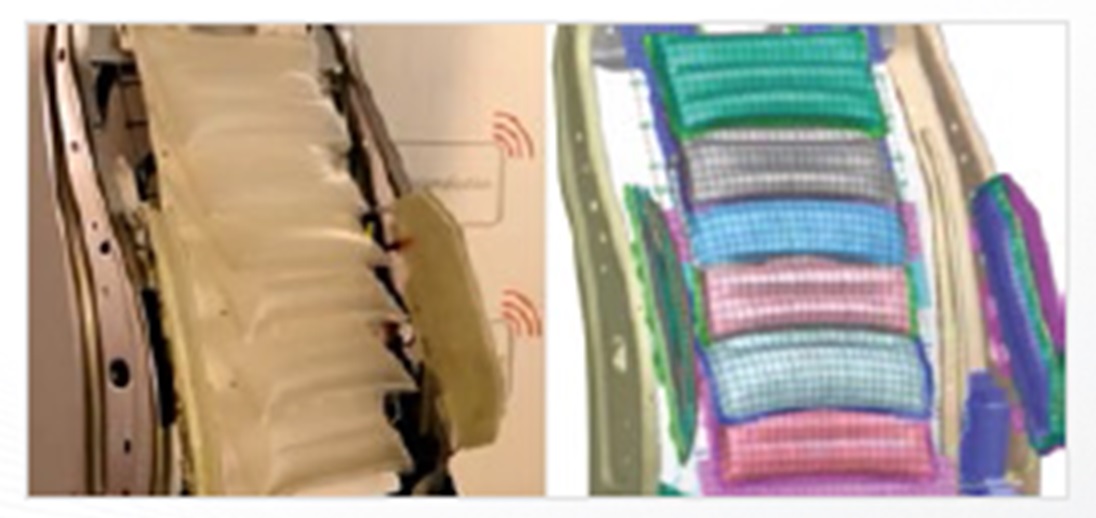

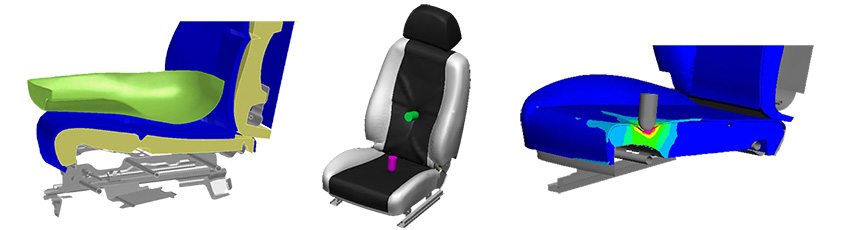

With ESI Virtual Seat Solution (VSS), you can seat the dummies or dedicated human models accurately and predict their final posture. Based on this precise posture, seat engineers can estimate pressure mapping, H-Point, softness-hardness or meat-to metal, and test virtually the seat comfort.

Thanks to the quick trim manufacturing prediction tool, and taking into account the seat trim manufacturing and assembly, engineers can seat the occupant fully virtually without the need of any real seat prototype.

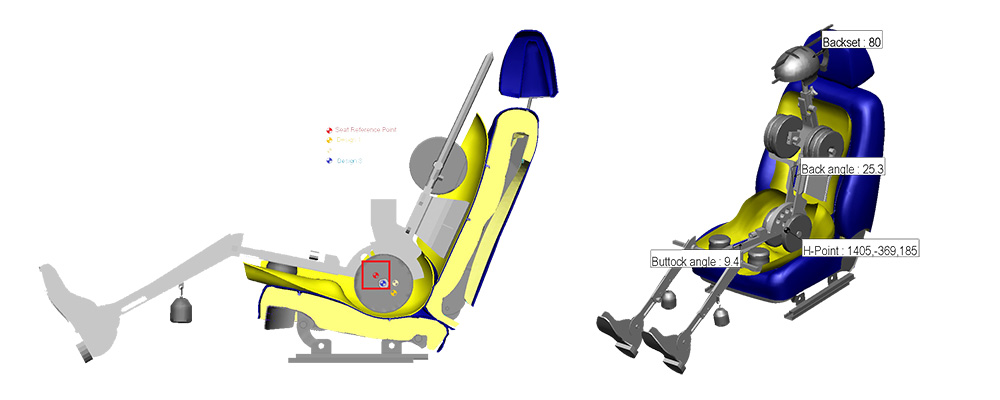

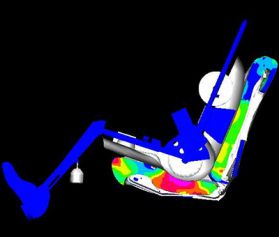

H-Point and other posture measurements

Dummies like HPM1, HPM2 and HRMD are included in Virtual Seat Solution and used for the prediction of H-Point, Backset value and other posture measurements through dedicated functionalities. Several international standards like the SAEJ826 are fully embedded in VSS for an easy set-up and analysis.

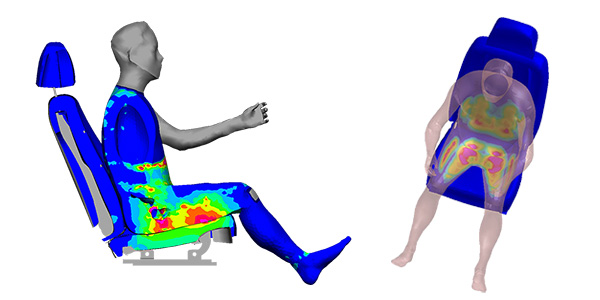

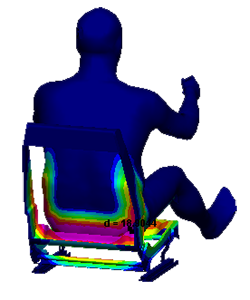

Pressure mapping

Using a set of scalable comfort human models, included in VSS, users can estimate the seat comfort performance through pressure mapping with integrated and customizable comfort criteria. Discomfort can thus be evaluated for several anthropometries and variants of seats can be easily compared.

Human models library

Human models from different anthropometries and populations are embedded and available in VSS, such as 5th, 50th, 95th percentile human models developed in partnership with HYUNDAI Motor Company.

ESI proposes also new human models for the Elderly, Overweight and Disabled to evaluate the (dis)comfort of the seat for a wide range of passenger population. Click here to read the last publications done on these new human models.

The detailed definition of all human articulations and the validated flesh properties enable inner stresses and contact pressure distribution.

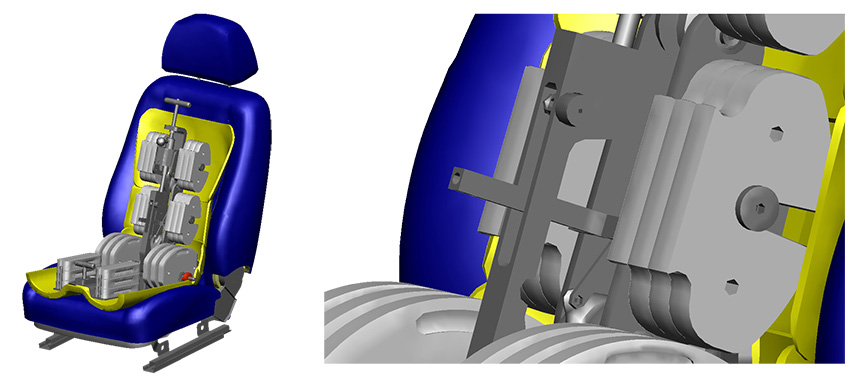

Lumbar support

VSS gives the option of integrating mechanical or pneumatic lumbar support into the virtual seat prototype for virtual analysis of the effect of the actuation of such a system on the occupant using, for instance, the HPM2 dummy – and to optimize such a system. Click here to watch how Lear used this.

Softness, hardness prediction

Virtual testing of initial softness and hardness is available with VSS through dedicated functionalities. International standards, such as SE J2896, are fully embedded for easy set-up and analysis. Virtual Seat Solution ensures the accuracy of the prediction thanks to the consistent chaining of stresses and strains coming from the trim manufacturing and assembly process.

Meat-to-metal

When seating the human models, Virtual Seat Solution accurately evaluates meat-to-metal, including the physical deformation of the seat.

The numerical result (H-Point, thigh, torso and back angles) approach the experimental responses well and allow realistics predictions. Virtual Seat Solution simulation technique is sensitive to the detailed seat characteristics. It is predictive enough to consider a virtual seat design process.

A. Savary, J. Makala, Renault Research Department, - IQPC Innovative Seating” conference, 2007